Small nozzle, big benefits

Introduction to micro-bubble

generating nozzle

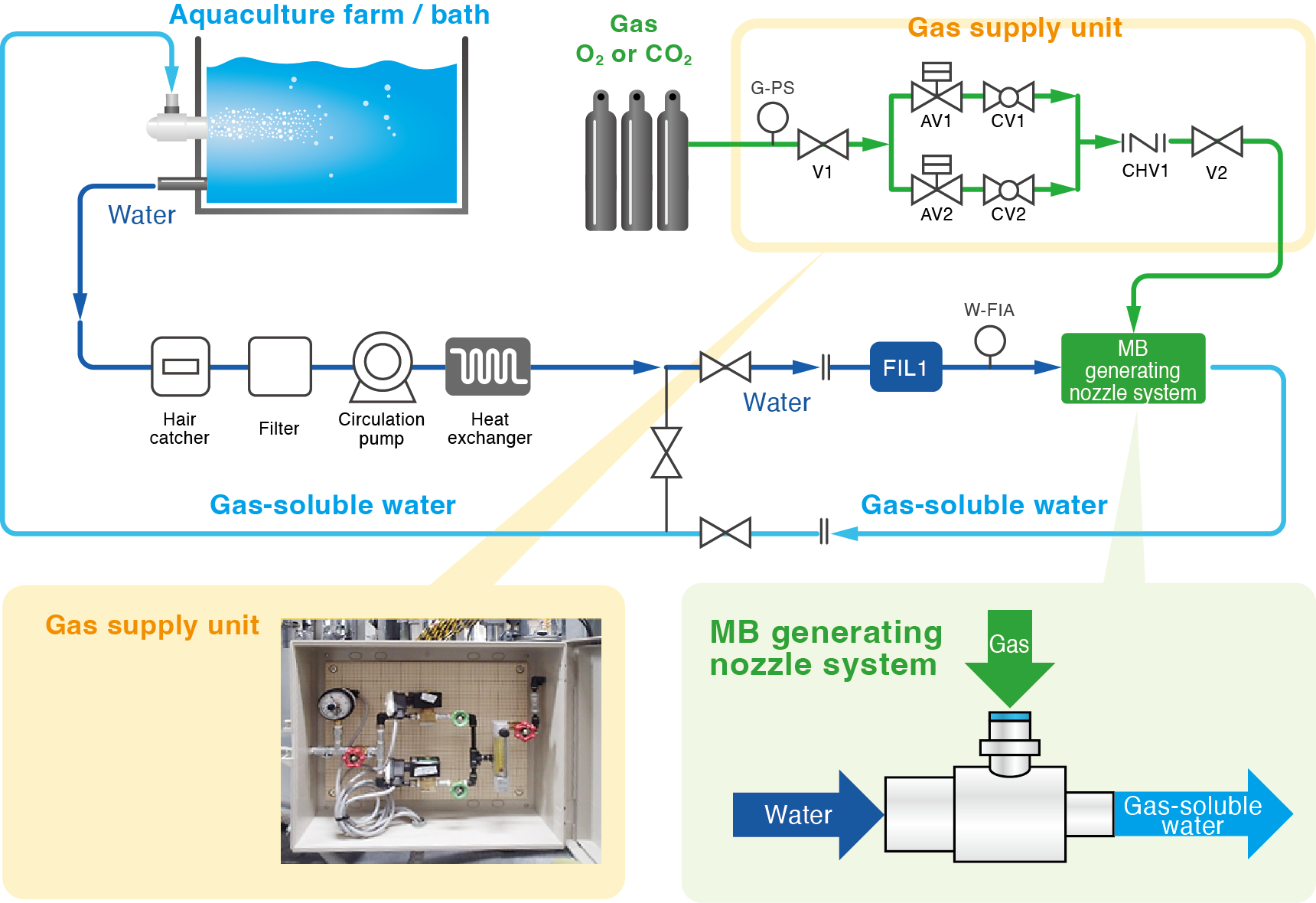

Introducing micro-bubbles to public baths and

aquaculture farms easily

Microbubbles of 1 μm to 100 μm are expected to provide visitors with health effects, such as skin beautification and blood flow promotion, in public baths (large-scale public bath & spa facilities, spas, etc.).

Micro-bubbles are also known to eliminate a deficiency of oxygen in water at aquaculture farms, helping the growth of aquatic organisms.

Using our small micro-bubble generating nozzle, you can easily introduce micro-bubbles.

Advantage of the micro-bubble generating nozzles

-

Low cost

Can be introduced at a lower cost than existing bubble generators!

-

High dissolving efficiency

Gas dissolves more easily in water, and thus higher effects can be expected!

-

Small space and easy installation

All you need to do is attach a small nozzle.*

There is no need for large-scale equipment!

* The installation method varies depending on the application.

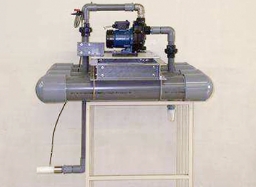

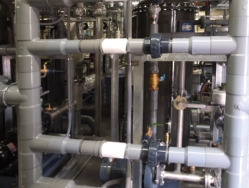

Low costExamples of components

Low costExamples of components

- Micro-bubble (MB) generating nozzle

- Example 1: Mounting on a general-purpose pump

- Example 2: Gas-liquid mixing system at an aquaculture pond

- Example 3: Carbon dioxide gas supply unit

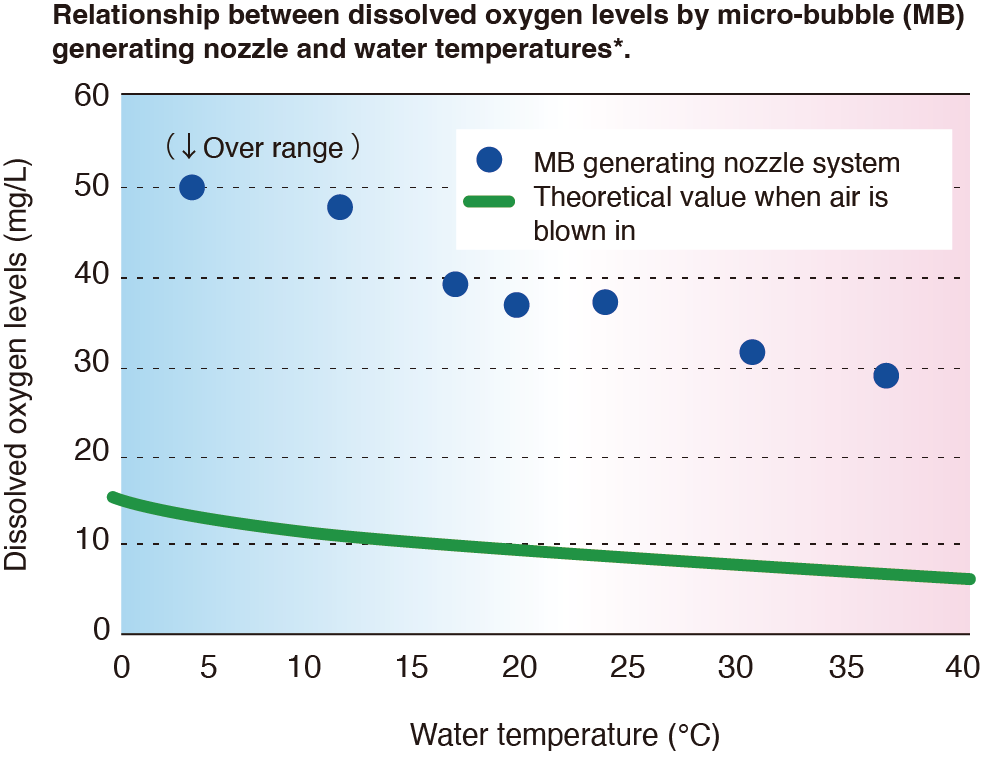

High dissolving efficiency

High dissolving efficiency

A Micro-bubble (MB) generating nozzle self-aspirates gas by utilizing the internal negative pressure generated by the change in the cross-sectional area of the water passage when water is pumped into the generating device, and it makes the gas aspirated by the water flow finer and spurts it out.

* Comparison between dissolved oxygen levels by our MB generating nozzle system and theoretical dissolved oxygen levels at the time of general air blowing (our test results)

| Blown gas | Oxygen |

|---|---|

| Gas blowing flow rate | 0.48NL/min |

| MB generating nozzle size | 25A |

| Water capacity | 81 L |

| Circulating water flow rate | 35L/min |

| Dissolved oxygen meter | DO-31P manufactured by DKK-TOA Corporation |

Furthermore, Micro-bubble (MB) generating nozzles are used to increase the amount of dissolved gas in the water at aquaculture farms and public baths because the following effects can be expected.

- At aquaculture farms

- Promoting growth of aquatic organisms

- In public baths

- Promoting blood circulation and beauty by carbon dioxide baths

Space-saving and easy installation

Space-saving and easy installation

All you need to do is attach a small nozzle. There is no need for large-scale equipment. Also, the nozzle main unit is small and space-saving.

It can be easily installed as it can be retrofitted to the piping.

Incorporate piping into the water circulation line

Product specifications

| Model | □15-A | □25-A | □40-A |

|---|---|---|---|

|

|

|

|

| Main unit material | Standard product: Polyacetal resin (POM) | ||

| Made-to-order product: Stainless steel (SUS304) | |||

| Materials other than the above (Common) |

Sphere: Teflon, Sphere support pin: SUS316 | ||

| O-ring: Nitrile rubber | |||

| Aspiration pipe fitting: PPCN6-1 manufactured by MISUMI Corporation | |||

| Foreign material passage diameter (mm) | 1.1 | 1.9 | 2.8 |

| Inner diameter (mm) | 15.0 | 26.0 | 39.0 |

| Connecting screw (R) | 1/2 | 1 | 1・1/2 |

| Aspiration section screw | Rc 1/8 | ||

| Maximum diameter x total length (mm) | 34×80 | 48×90 | 90×110 |

| Weight (made of resin, g) | Approx. 70 | Approx. 140 | Approx. 250 |

- 1. Specifications are subject to change without notice, so please check before purchasing.

- 2. □ in the model column indicates the material identification code (P for POM, S for SUS304).

- 3. Delivery time: 3 to 4 weeks when the standard product is out of stock, 4 to 6 weeks for made-to-order SUS products

- 4. Please note that the user is responsible for verifying that the material used is suitable for the environment in which it will be used.