Impurity concentration: less than 1 ppb

Introduce Ultrahigh-Purity Gas Easily

Equipment for stably supplying ultrahigh-purity gases required for

industry

Various high-purity inert gases (argon, nitrogen, etc.) and hydrogen (H2), which play an important role as zero gas for

microanalyzers, explosion-proof shielding gas for welding or as the foundation for ultra-precision processing technology, can be

refined to ultrahigh purity by removing impurity components using easy-to-introduce in-line equipment.

Concerns about introduction of ultrahigh-purity gas equipment

-

We want to use ultrahigh-purity gas but

are concerned about the cost.

-

We have no space for gas purification equipment.

-

We want to use only a small amount of ultrahigh-purity gas.

-

We do not have enough flow with an inline system and are concerned about the cost.

-

We are also concerned about running costs and maintainability.

All problems solved by Osaka Gas Liquid's high-purity gas purification equipment

Features of high-purity gas purification equipment

-

Refining ultrahigh-purity gas

Impurity concentration:

less than 1 ppb

99.999 vol% minimumIt refines gas to ultrahigh purity through a combination of multiple catalysts and adsorbents.

-

Helping improve economy and reduce costs

The adsorbents are renewable, requiring no replacement.

The simplified structure has reduced production costs.

No utilities are required.

The renewable adsorbents for impurities and the simplified structure help reduce both initial and running costs.

-

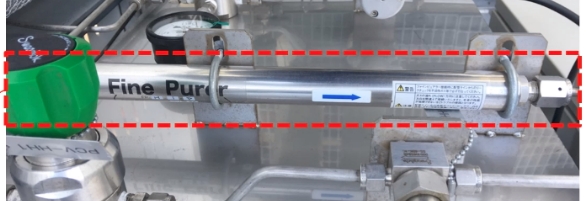

Compact, space-saving inline system

It can be used simply by attaching it to the existing gas facilities. Further compactness is achieved through the use of newly developed catalysts.

-

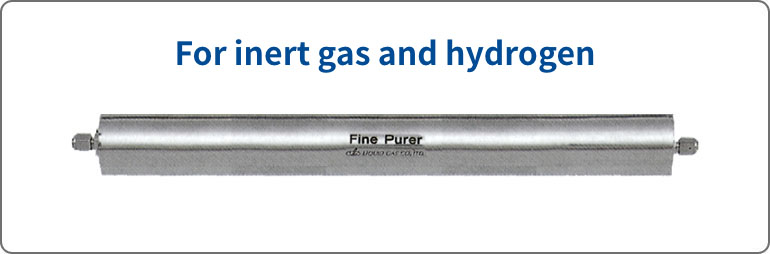

Compatible with two types of gases: inert gases and hydrogen

A lineup from 3 liters to 300 liters per minute is available for purification of various gases, including inert gas and hydrogen.

Main applications

-

Carrier gas/

zero gas for

microanalyzers -

Shield gas for welding

-

Atmospheric gas

Purge gas

For a variety of semiconductor manufacturing equipment, CVD equipment, etc.

(For equipment requiring high purity)

Product lineup

Low-cost type [Fine Purer]

A continuous supply type that does not require renewal work is also available.

- ・ By automatically switching between the two purification cylinders, continuous purification is possible.

- ・ Custom-made according to customer needs

Specifications

| Model | Fine Purer | ||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Gas type | For inert gas, hydrogen and air | ||||||||||||||||||||||||||||||

| Flow rate | 3~300NL/min | ||||||||||||||||||||||||||||||

| Utilities | Not required | ||||||||||||||||||||||||||||||

| Guaranteed purification values |

(unit: ppb) |

New product

[Fine Purer Getter Type]

FPI-1GTR

![[Fine Purer Getter Type] FPI-1GTR](../img/product/gas02/img-11.jpg)

[Features]

(1) Removing impurities to the utmost limit

| Applicable gases | Noble gases: He, Ne, Ar, Kr and Xe |

|---|---|

| Impurity concentration in feedstock gas |

Total 10 ppm (5N) max. |

| Impurity concentration in refined gas |

Total 10 ppb (8N) max. |

| Impurities to be removed | H2 ,N2 , CH4 , O2 , CO , CO2 , H2O |

(2) Power supply box integrated

A simplified structure equipped with a power supply box as standard

(3) With safety function

It has the function of automatically preventing the heater from overheating.

(4) RoHS-compliant

(5) Delivery possible in one week*

* Please consult us when ordering multiple units.

Specifications

| Model | FPI-1GTR |

|---|---|

| Maximum pressure | 1.0MPaG |

| Working pressure | 0.5MPaG |

| Maximum flow rate | 1.0L/min |

| Dimensions | Φ 114mm × H 472mm |

| Weight | 7.8㎏ |

| Power supply | 100VAC |

| Power consumption | 55W |

| Connection diameter | 1/16 inch Swagelok (female) |

Organizations that have introduced our equipment

Various manufacturers and university research institutes

- Semiconductor related

- Optical fiber related

- Automotive related

- Analyzer

- Precision equipment