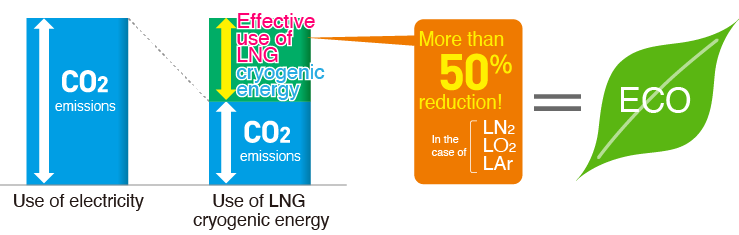

Environmentally friendly gases with 50% reduction of CO2 emissions (using LNG cryogenic energy)

Please Contact Osaka Gas Liquid for your industrial gas needs.

We deliver liquefied oxygen, liquefied nitrogen, liquefied argon and

liquefied carbon dioxide in a flexible manner.

We flexibly provide a wide range of industrial gases that are indispensable in a wide range of industries

(food, medical, construction, automotive, steel, ceramics, chemical and electronics) according to the purpose and usage conditions of our customers.

We also have experience in purging and airtight work. Please feel free to contact us.

Features of industrial gases sold

by Osaka Gas Liquid

Environmentally friendly

Osaka Gas Liquid's liquefied gas products are produced from oxygen, nitrogen, and argon in the air and carbon dioxide gas supplied from adjacent plants at power-saving and high-efficiency liquefaction plants that effectively use the cryogenic energy from liquefied natural gas (LNG), which is a feedstock for city gas.

-

Stable supply

We have two industrial gas production sites, enabling us to supply gases stably.

-

Safe supply

We have a complete inspection and maintenance system in place to respond promptly to statutory and voluntary inspections required by the High Pressure Gas Safety Act, as well as to emergency situations.

Gases dealt with

We deal with the following industrial gases.

-

![Liquefied oxygen [-183°C]](../img/product/gas/img-04.jpg)

Liquefied oxygen

[−183℃]It is used in various fields, including steel, melt-cutting, medical, sewage and industrial wastewater treatment, and also plays a role in the development of next-generation technologies, including space exploration and biotechnology.

Melt-cutting work

Medical oxygen

-

![Liquefied nitrogen [-196°C]](../img/product/gas/img-05.jpg)

Liquefied nitrogen

[−196℃]It is used for a wide range of applications, including as atmospheric gas for semiconductor manufacturing and metal heat treatment, security and purge gas in chemical plants, for medical use, for frozen food production using cryogenic energy and for cryogenic grinding.

Cryogenic grinding (LINREX MILL)

Filling nitrogen

-

![Liquefied argon [-186°C]](../img/product/gas/img-06.jpg)

Liquefied argon

[−186℃]In addition to being widely used for welding high-grade metals, it is also commonly used in steelmaking processes, semiconductor manufacturing and, in fields familiar to us, as an encapsulated gas in light bulbs and fluorescent lamps.

Welding work

Semiconductor manufacturing

-

![Liquefied carbon dioxide [-23°C 2.0 MPaG]](../img/product/gas/img-07.jpg)

Liquefied carbon dioxide

[−23℃ 2.0MPaG]It is used for cooling and storage of food, for carbonated drinks, and as an inert gas for welding and fusing. Dry ice is used to freeze various food products and ice cream for storage and transportation.

Drink

Dry ice

Physical properties of industrial gases

| Oxygen | Nitrogen | Argon | Carbon dioxide | |

|---|---|---|---|---|

| Property |

・ Colorless, tasteless and odorless ・ Chemically active ・ Highly oxidative |

・ Colorless, tasteless and odorless ・ Chemically inert |

・ Colorless, tasteless and odorless ・ Chemically inert |

・ Colorless, tasteless and odorless ・ Chemically inert |

| Chemical formula | O2 | N2 | Ar | CO2 |

| Molecular weight | 32 | 28 | 40 | 44 |

| Gas density (kg/m3) | 1.429 | 1.251 | 1.783 | 1.977 |

| Gas specific gravity (air = 1) | 1.11 | 0.97 | 1.38 | 1.54 |

| Liquid density (kg/l) | 1.141 | 0.809 | 1.398 | 1.03 |

| Boiling point (°C) | -183 | -196 | -186 | -78.5 |

| Latent heat of vaporization (kcal/kg) | 50.9 | 47.7 | 39.8 | 137 |

| Product purity (minimum) |

99.8% | 99.999% | 99.9995% | 99.95% |

How to supply industrial gases

We will make a proposal based on the amount of usage.

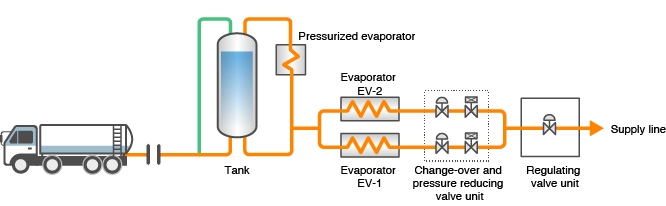

Liquefied gas storage tank (CE) method

A vacuum liquefied gas storage tank (CE) that stores liquefied nitrogen (-196°C), liquefied oxygen (-183°C) or another low-temperature liquefied gas and an evaporator for vaporizing and raising the temperature of the liquefied gas are installed at the plant site to provide near room temperature gas.

Amount of usage (approximate): 3,000 m³/month or more

Schematic flow chart

-

Individual cylinder and cylinder bundle methods

- Individual cylinder method

-

Gas is filled and supplied in a 47-liter capacity cylinder.

Furthermore, by installing two systems each of which consists of around 10 of these cylinders connected with a header, gas supply can be switched manually or automatically between the two systems.

- Cylinder bundle method

- Gas is supplied by installing a unit consisting of around 10 to 20 cylinders connected on a trestle.

Amount of usage (approximate): 200 to 2,000 m³/month

-

LGC method

- Liquefied gas is filled into a 175-liter capacity portable container or a 1,000-liter capacity mobile container. A multiple number of these containers are stocked for gas supply according to the amount of usage.

Amount of usage (approximate): 1,000 to 3,000 m³/month

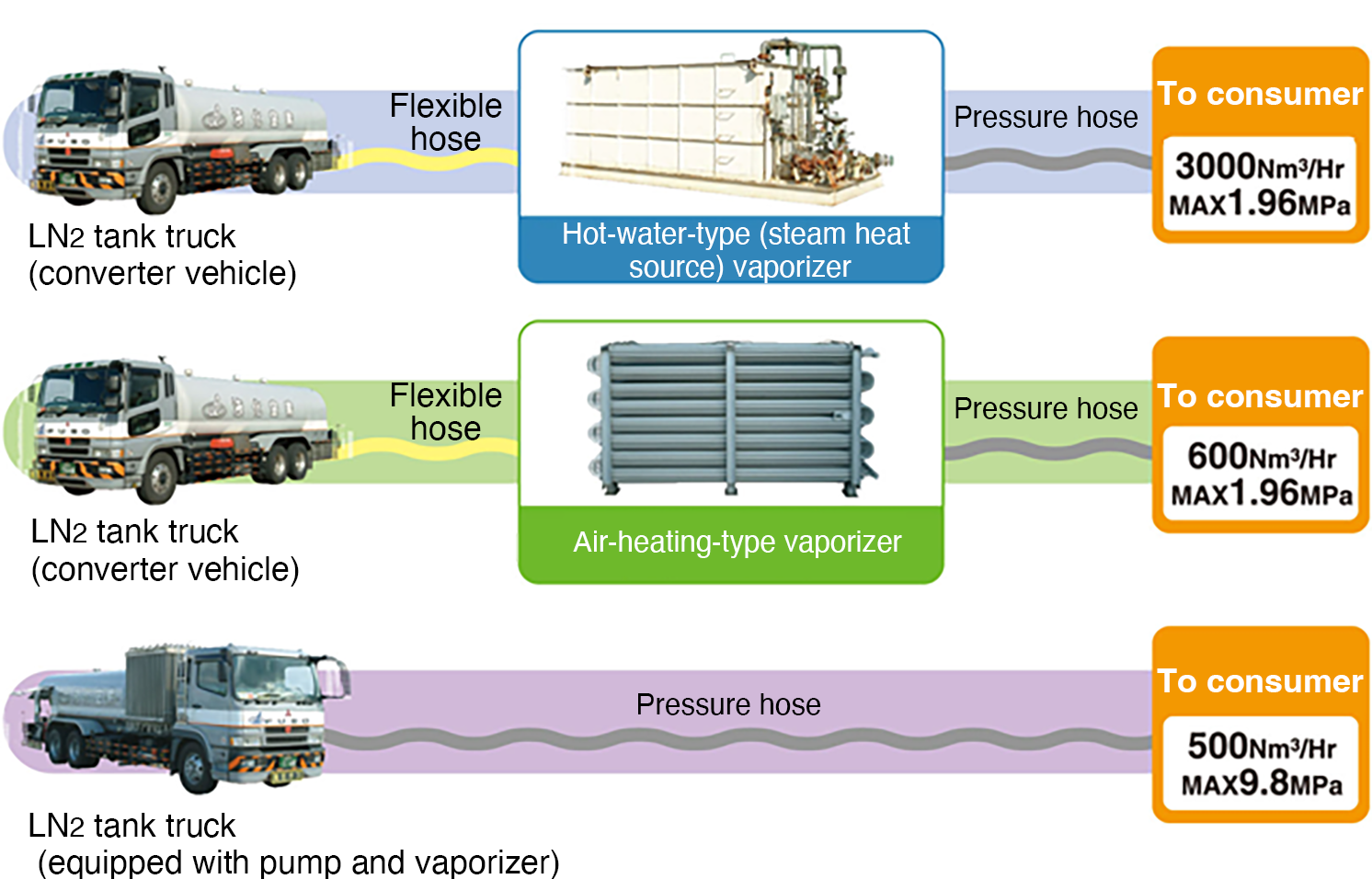

Gas supply for purging work and pressure and airtightness tests

We can also supply gases for a short period of time for purging work and pressure and airtightness tests of gas tanks, LPG facilities, piping, etc.

We own ancillary equipment according to your usage.

Other supply method

NICE-crete method

(Pre-cooling of concrete)

We provide quality control and refrigeration management of concrete, from cooling to casting, based on our extensive experience and track record in cooling various structures for various purposes, including use in preventing cracking of large-scale high-strength concrete.

The Nitrogen Cooling for hi-Endurance Concrete (NICE-crete) method is a new pre-cooling technique that uses liquefied nitrogen as a refrigerant. Using cryogenic liquefied nitrogen as the refrigerant has removed the limitation in refrigeration volume and expanded its applications in prevention of cracking under the conditions that pre-cooling with cold water or ice alone had been impossible to prevent cracking. Moreover, it can improve the strength of structural concrete as well as not affecting the quality of concrete. We have established concrete quality control and refrigeration management methods, from cooling to casting, based on our extensive experience and track record in cooling various structures for various purposes, including use in preventing cracking of large-scale high-strength concrete. Furthermore, since we have developed refrigeration facilities for both field installation and plant installation, we can perform the most appropriate cooling work according to the grade and cost required by the customer, adapted to the concrete cast volume, cast speed, site size and various other conditions.

Applications of the NICE-crete method

- 1. High-strength concrete structures

-

・ PC bridge

・ PC tank and dike

・ PC silo

・ High-rise RC

- 2. Concrete structures and piers with large cross sections

-

・ Dam

・ Large machine foundation

・ Underground and aboveground tanks

- 3. Concrete that is built in hot weather

- 4. Structures requiring particular attention to cracking and strength