Recovering and effectively using carbon dioxide (CO2)

Helping to Curb Global Warming

Producing liquefied carbon dioxide and dry ice

Liquefied carbon dioxide and dry ice are necessary for industry and daily life and are used in a wide range of applications,

from familiar food products and beverages to the manufacturing industry and the space industry.

We produce such indispensable liquefied carbon dioxide and dry ice in an environmentally friendly manner, thereby helping to curb global warming.

Features of our liquefied carbon dioxide

Energy-efficient and environmentally friendly production method

We produce liquefied carbon dioxide and dry ice while contributing to environmental conservation by utilizing the cryogenic energy

of liquefied natural gas (LNG) at -167°C.

Located within Senboku LNG Terminal I, Osaka Gas Co., Ltd., we utilize the cryogenic energy generated when liquefied natural gas

(LNG), which is a feedstock for city gas, is vaporized to liquefy carbon dioxide gas at a lower pressure than that at conventional

production plants, thus contributing to energy conservation by reducing power requirements.

Main applications

Liquefied carbon dioxide is widely used in industrial, food and chemical applications.

Arc welding

Soft drink

Neutralization of alkaline wastewater

Extinguishing fire

For casting

For cooling media

Plant factory

Pharmaceutical and additive

Dry ice

Dry ice blasting

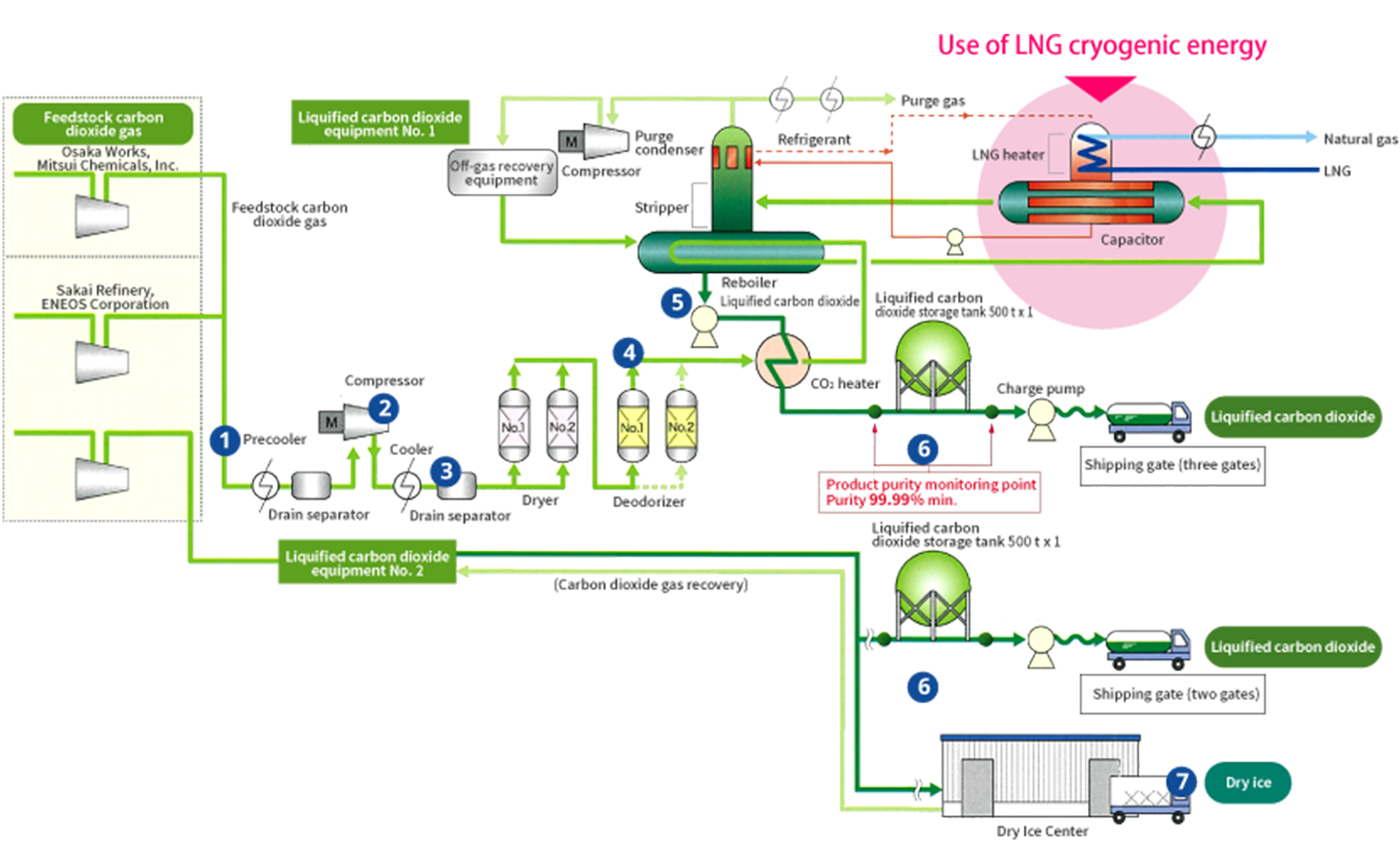

How liquefied carbon dioxide and dry ice are produced

1 Acceptance of carbon dioxide gas as a feedstock (35°C, 0.035 MPaG)

Carbon dioxide gas sent to the factory is accepted, and some of the moisture content is separated.

2 Compression (170°C, 0.84 MPaG)

The carbon dioxide gas is compressed at high pressure to separate the moisture content.

3 Cooling and precooling (170°C -> 40°C -> 13°C)

The carbon dioxide gas is pre-cooled in stages.

4 Drying and deodorization

The pre-cooled carbon dioxide gas is then dried and deodorized.

5 5 Cooling, liquefaction and purification through heat exchange with LNG

The carbon dioxide gas is cooled, liquefied and purified using the cryogenic energy generated during vaporization of LNG.

6 Storage and shipment of liquefied carbon dioxide (-23°C, 2.0 MPaG)

The liquefied carbon dioxide is stored in storage tanks at high pressure and low temperature, and it is shipped by tank truck or other means.

7 Production and shipment of dry ice (-79°C)

The liquefied carbon dioxide is pressed and compressed and shipped as hard dry ice.

Dry ice is cut into blocks of approx. 25 kg each, and 36 blocks are packaged per flexible container for shipment.

Production capacity

Liquefied carbon dioxide production equipment

| Name | Specification |

| Production capacity | 250 tons/day |

| Liquefied carbon dioxide storage tank | 500 tons x 2 |

Dry ice production equipment

| Name | Specification |

| Dry ice press | Production capacity 26 tons/day x 2 |

| Dry ice storage | Rack type, 81 tons |

Dry Ice Center

-

Press

-

Band saw

-

Packaging machine

-

Cross strapping machine

-

Palletizer

- Dry ice press

- : 2

- Automatic packaging machine

- : 1

- Automatic palletizer

- : 1

- Rack-type dry ice storage / Capacity 81 tons

- : 1

Company engaged in producing and selling liquefied carbon dioxide and dry ice

Nagaoka Carbonic Co., Ltd.

Nagaoka Carbonic Co., Ltd.

Nagaoka Carbonic Co., Ltd. was established in September 2018 with a 100% investment from Osaka Gas Liquid Co., Ltd. and began commercial operation in November 2020.

Carbon dioxide gas supplied from a domestic gas field

We produce and sell liquefied carbon dioxide and dry ice from carbon dioxide gas supplied by INPEX Corporation (Nagaoka Field Office), utilizing catalytic adsorption and other process technologies that the Daigas Group has cultivated over the years.