Fast, Safe & Sanitary and Low Cost

Proposal for Dry Ice Blasting

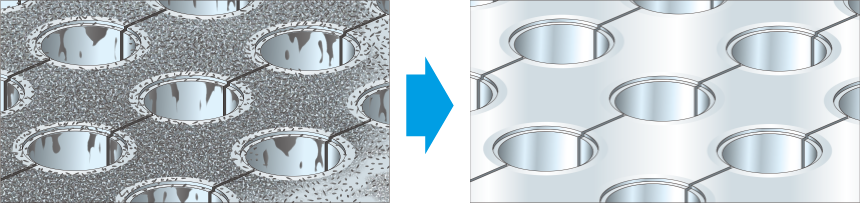

No damage to the objects to be cleaned and no residue left behind

Dry-ice blasting is a shot blast technique that removes dirt from objects by blasting dry ice particles with the power of compressed air.

Since dry ice sublimates (or gasifies) as soon as it hits molds, dry ice blasting eliminates the need for collection and post-treatment of residual materials, such as blast media and solvents used in other cleaning methods.

Advantage of dry ice blasting

-

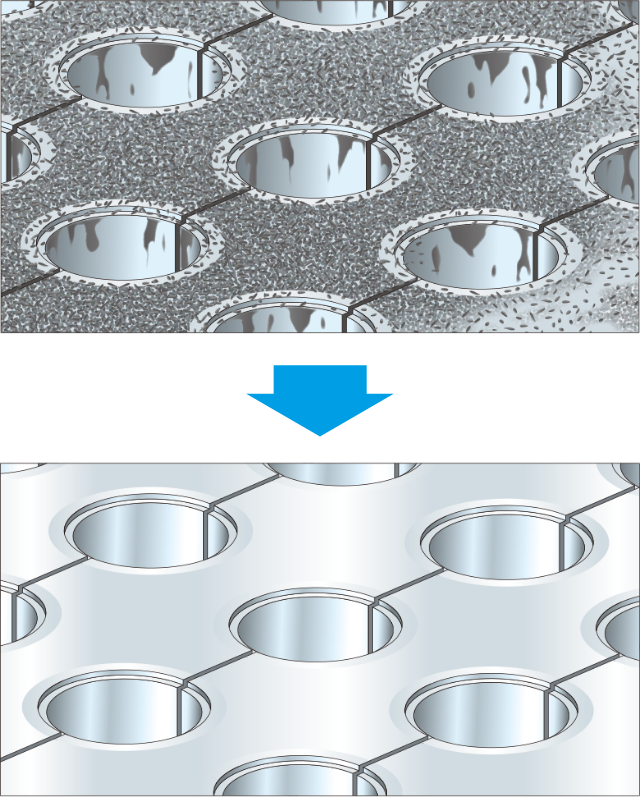

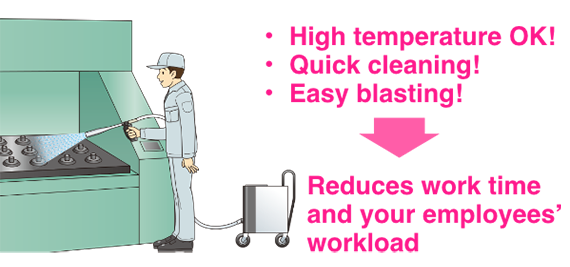

Simply, Fast!

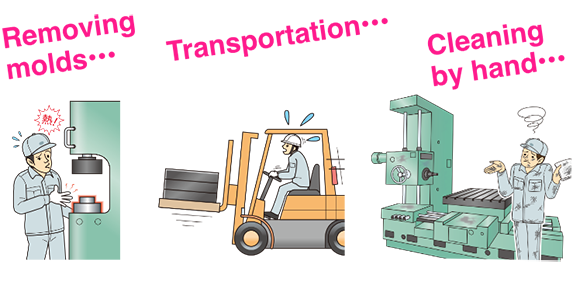

For example, when cleaning molds, manual cleaning requires waiting until the hot molds cool down, removal, transportation, and other pretreatment steps.

Dry ice blasting requires no pretreatment! Molds can be cleaned quickly even at high temperatures! Easy blasting reduces work time and your employees’ workload.

-

Cleaning is Safe & Sanitary!

Safe for both people and molds

Dry ice sublimates (or gasifies)

upon impact and disappears.Dry ice sublimates (or gasifies)

as soon as it hits the molds and disappears.

Less residues are left after cleaning,

leading to labor savings.*No rinsing, drying,

or water treatment processes are required.Dry ice is nontoxic and non-flammable. Since dry ice blasting does not require use of organic solvents, it is safe and secure for your employees and friendly to the environment. Furthermore, it does not require collection or post-treatment of blast media used for plastic blasting, organic solvents and other residues, which leads to significant labor savings compared to conventional methods.

* Since dirt and other residues on the object to be cleaned are scattered by dry ice, it is necessary to collect such dust with a broom or similar tool.

-

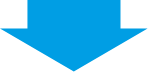

No waste, Low Cost!

Dry ice blasting requires no pre-treatment and post-treatment, thus significantly reducing work time. Also, the high cleaning power reduces product loss due to dirt adhesion. This improves productivity and leads to further cost reductions.

Cleaning principles and features

Impact cleaning

Since dry ice blasting uses dry ice, whose hardness is low, there is no risk of damaging the object to be cleaned.

Dry ice pellets impact the object to be cleaned at high speed, and the impact first removes dirt.

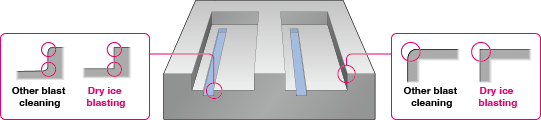

Quality improvement

Since dry ice particles have low hardness, they can remove dirt without abrading the surface of the base material.

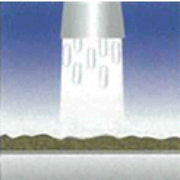

Sublimation cleaning

Upon impacting the object to be cleaned, dry ice pellets at -79°C instantly sublimate from a solid to a gas form.

At this time, dry ice changes into a gas approximately 750 times its volume.

This explosive sublimation pulls dirt off the surface.

Cost reduction

Since dry ice gasifies as soon as it hits the base material, no blast media remain.

This eliminates their collection and disposal and other additional treatment steps, reducing cost.

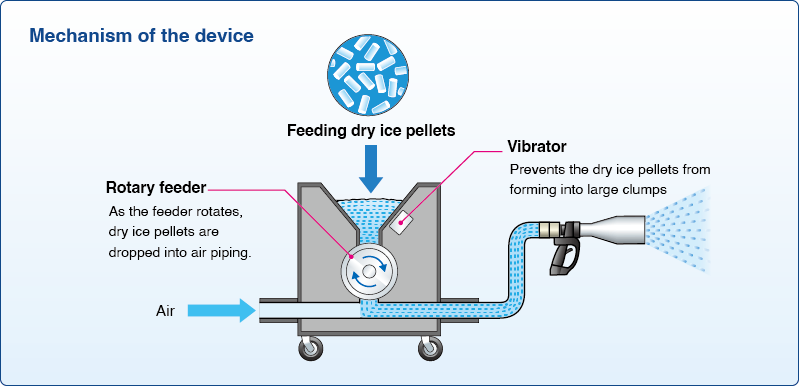

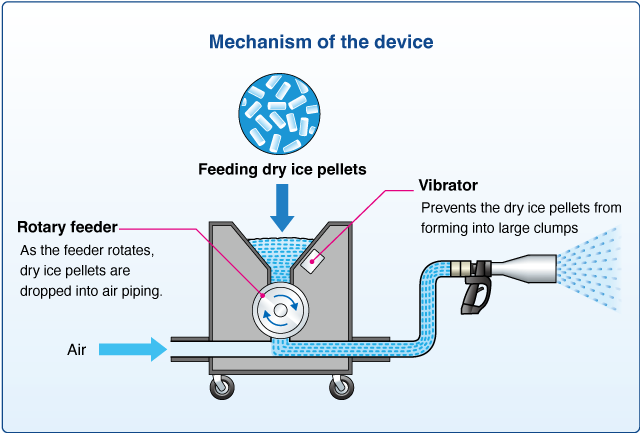

System configuration

Comparison with other cleaning methods

○ = Applicable

| Cleaning method | No secondary waste generated | Nonconductive | Nontoxic | Nonabrasive |

|---|---|---|---|---|

| Dry ice blasting | ○ | ○ | ○ | ○ |

| Sand blasting | × | ○ | ○ | × |

| Soda cleaning | × | ○ | ○ | × |

| Water washing | × | × | ○ | ○ |

| Manual tools | ○ | × | × | × |

| Chemicals | × | × | × | ○ |

Main applications and cleaning examples

Dry ice blasting is useful for many customers.

- Textile industry

- Removal of tar stains from textile dryers

- Forging industry

- Cleaning of forging dies

- Rubber and tire industry

- Removal of rubber residues and mold release agents carbonized or adhered to molds

- Resin industry

- Removal of polymer materials and mold release agents carbonized or adhered to molds

- Aluminum industry

- Cleaning of aluminum casting and die-casting molds (removal of mold release agents)

In addition to the above, dry ice blasting and surface treatment are used effectively in a wide range of industries and applications shown below.

Dry-ice cleaning system for precision instruments

This is a dry ice blaster ideal for desktop cleaning.

This device is ideal for cleaning boards, semiconductors and other small devices.

— Features —

- Cleans particles and oil and fat content

without damaging boards, etc. - Dry ice powder made from liquefied CO2 is jetted out to clean particles and oil and fat content without damaging the objects to be cleaned.

- No drying and

water treatment processes required - No washing water is required, eliminating the need for drying and water treatment processes.

- Pollution-free eco-friendly cleaning

- Since this system uses CO2, which is present in the atmosphere, it achieves nonflammable, nontoxic, safe, pollution-free and environmentally friendly cleaning.

— Objects to be cleaned —

- Image industry

- Precision lenses, optical sensors and mobile phone lenses

- Semiconductor and electronic components

- Si, InP and GaAs wafers, photomasks, printed circuit boards, and hard disks

- Others

- Removal of foreign matter from molds/dies and ceramics and burrs from battery cells, etc. and artwork repair

ー Examples of cleaning ー

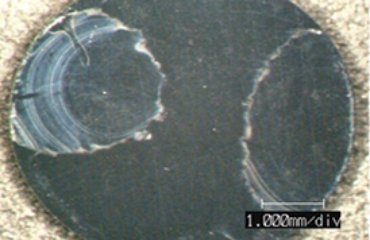

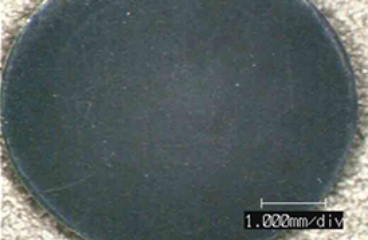

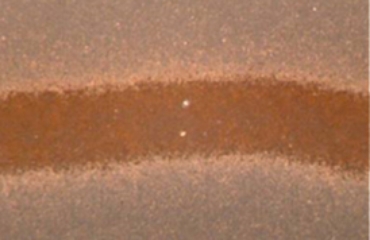

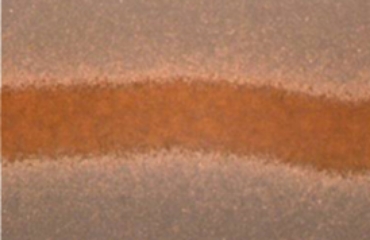

Workpiece: Carbide part Dirt: Adhesive

- Before cleaning

- After cleaning

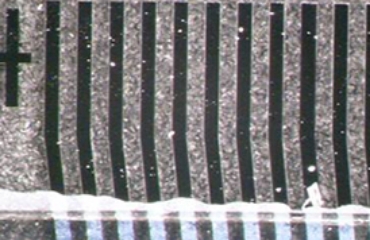

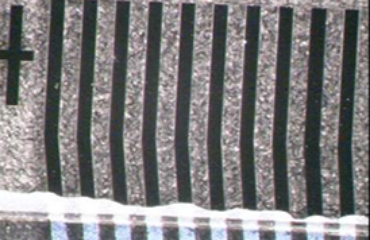

Workpiece: Film solar cell

Dirt: Pattern residue

- Before cleaning

- After cleaning

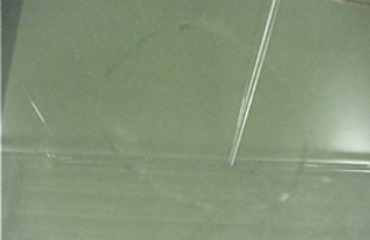

Workpiece: Glass plate Dirt: Fingerprint

- Before cleaning

- After cleaning

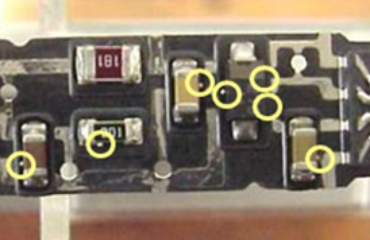

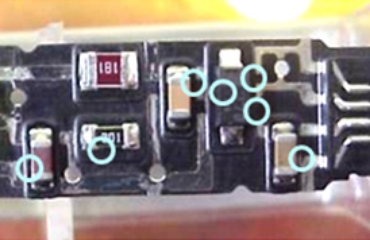

Workpiece: Bare board Dirt: Stain

- Before cleaning

- After cleaning

Workpiece: Precision motor

Dirt: Oil and metal powder

- Before cleaning

- After cleaning

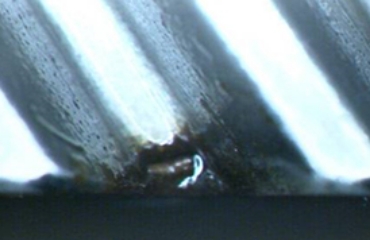

Workpiece: Automobile part

Dirt: Solder residue (0.24 mm or less)

- Before cleaning

- After cleaning

Workpiece: Organic EL Dirt: Glass particle

- Before cleaning

- After cleaning

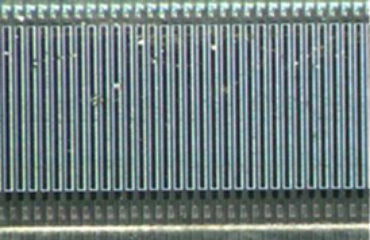

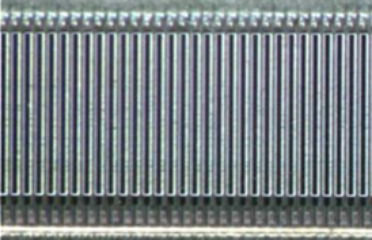

Workpiece: LCD terminal Dirt: dust

- Before cleaning

- After cleaning