On-site hydrogen generation system

* HYSERVE is a registered trademark of Osaka Gas Co., Ltd.

Supplying high-quality hydrogen at low cost, without trouble and in an easy

manner

Product lineup

A wide range of products are available depending on the amount of usage.

| Model |  HYSERVE-30 |

HYSERVE-100 |

HYSERVE-300X |

|---|---|---|---|

| Feedstock | City gas (13A) or propane gas | ||

| Hydrogen production capacity | 30Nm3/h | 100Nm3/h | 300Nm3/h |

| Hydrogen purity | 99.999% min. | ||

| Hydrogen supply pressure | 0.70 MPaG max. | ||

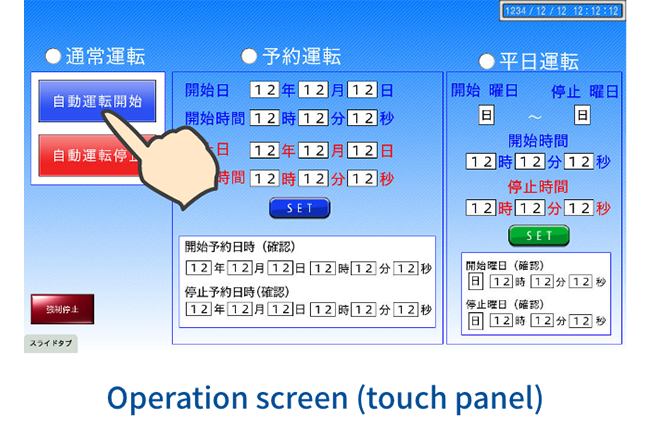

| Operability | One-touch automatic operation, adjustable load (40 to 100%), standby operation | ||

| Minimum unit size |

3,600W×2,000D×2,950H Excluding the auxiliary area |

5,300W×2,600D×3,300H Excluding the auxiliary area |

8,000W×3,000D×3,700H Excluding the auxiliary area |

* Hydrogen recovery equipment is available separately.

Click here for the process flow.

Click here for the process flow.

A separate window will open.

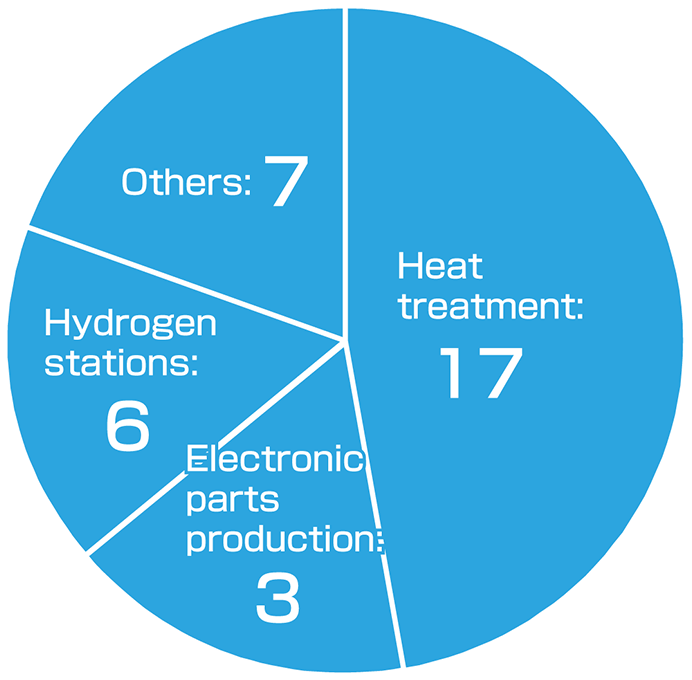

Delivery record

We have a delivery record of sales not only in the Kansai region but also throughout Japan.

Motomachi Plant,

Toyota Motor Corporation

* Excerpt from a press release article of

Toyota Motor Corporation

Plant

Kita-Osaka Hydrogen Station

Six benefits of HYSERVE

-

1: No initial investment (low running costs)

-

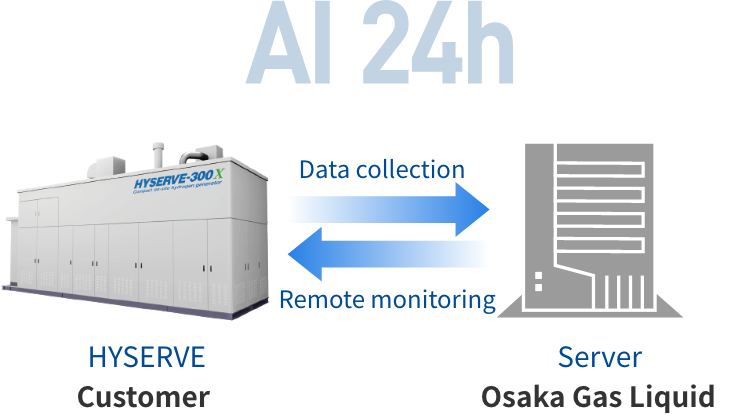

2: High reliability (AI monitors operational status 24 hours a day.)

-

3: No specialized engineers required

-

4: Not classified as hazardous materials and not subject to the High Pressure Gas Safety Act

-

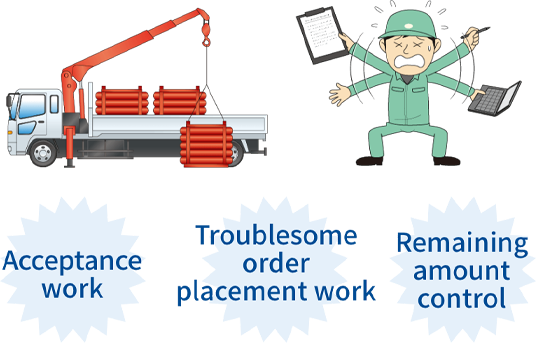

5: No need for troublesome cylinder loader/bundle receiving operations

-

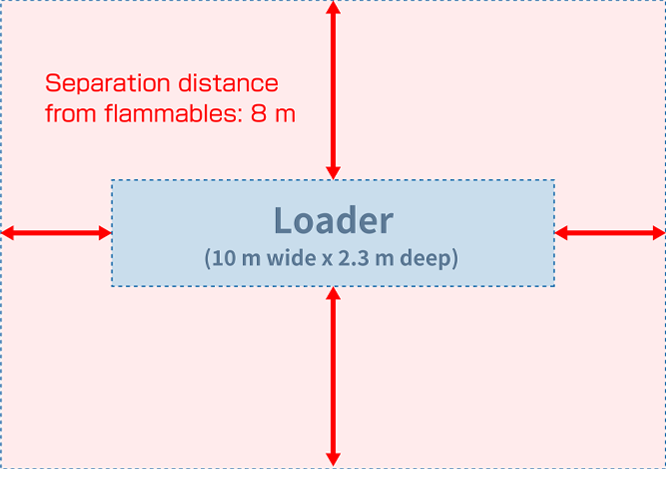

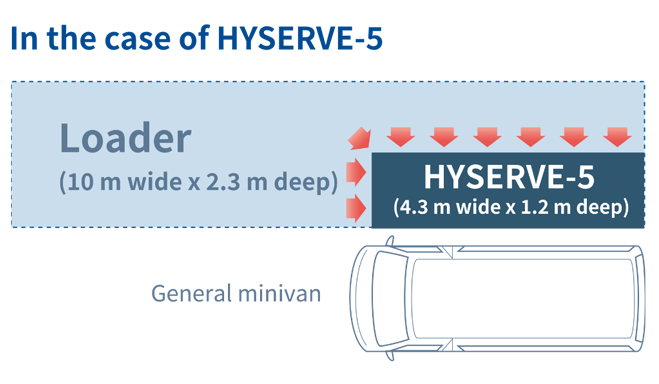

6: High flexibility in installation location

Do you have any problems with procuring hydrogen?

-

1

Hydrogen purchase costs are high.

Monthly hydrogen purchase costs are high.

Initial costs are high.

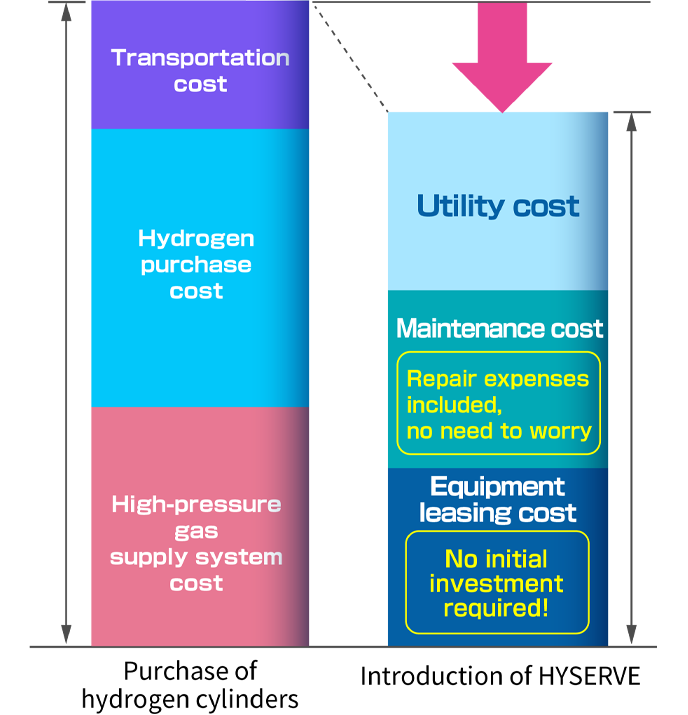

Low cost with no initial costs and maintenance cost included

On-site hydrogen production enables low-cost supply.

-

2

We are worried about problems with on-site machines.

Machinery seems to have a lot of trouble.

High reliability (AI monitors operational status 24 hours a day.)

-

3

We have no specialized engineers.

We have no specialized engineers who can operate

and/or maintain the system.

No specialized engineers required

Operation is fully automatic. (The system can be turned on and off at the touch of a button.)

Maintenance can be outsourced to us, eliminating the need for specialized engineers. -

4

Handling feedstock gas (hazardous and deleterious substances) and high-pressure gas is difficult.

When ammonia, methanol or high-pressure gas is used as a feedstock, assignment of qualified personnel is required and

authorization needs to be obtained.

Not classified as hazardous materials and not subject to the High Pressure Gas Safety Act

Since city gas or propane gas is used as a feedstock, there is no need for assigning qualified personnel or obtaining

authorization, allowing for easy introduction. -

5

We do not want to do troublesome cylinder loader/bundle receiving operations.

No need for troublesome receiving operations

-

6

It would require a large space for installation, but there is no place for that.

It would require a large space, including separation distance, but there is no place for that.

It is space-saving and not subject to the High Pressure Gas Safety Act, allowing for a high degree of freedom.

It can be installed in a small space and is not restricted by the High Pressure Gas Safety Act.

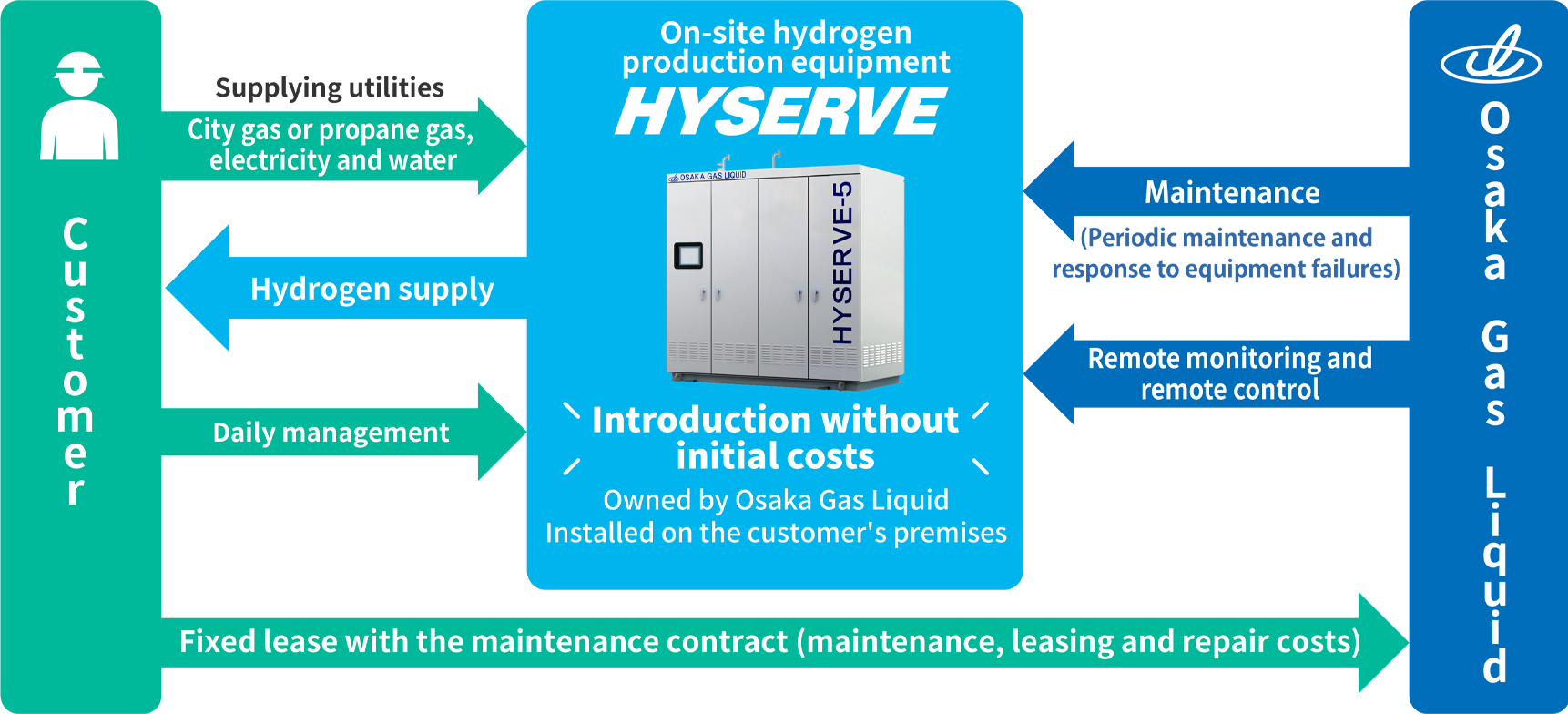

Basic scheme of on-site hydrogen contract

Customers can use the equipment without making an initial investment and reduce the costs required for delivery.

● We produce and supply hydrogen on-site by installing hydrogen generation equipment (HYSERVE) on the customer's premises.

● The customer is responsible for providing utilities (city gas or propane gas, electricity and water) necessary for hydrogen generation.

● The HYSERVE" is equipped with a remote monitoring system, and we will maintain and manage the equipment.

● The contract includes the maintenance, leasing and repair costs, enabling customers to use the equipment without initial investment.

● We will propose the best scheme for your needs.

Major industries where hydrogen is used

Main application fields

-

Metal

・ Powder metallurgy

・ Metal heat treatment

・ Magnetic iron powder

・ Metal sintering, etc.

-

Glass and ceramics

・ Flat glass manufacturing

・ Quartz glass manufacturing

・ Quartz glass processing

・ Optical fiber

・ Ceramic packages, etc.

-

Electricity and chemistry

・ Flameproofing of electronic devices

・ Semiconductors

・ Silicon wafers

・ Hydrogenated petroleum resins

・ Chemical products, catalysts, etc.

-

Food

・ Hydrogenation of fats and oils

・ Quality improvement of fats and oils

・ Sweetener use

-

Hydrogen stations

Hydrogen supply to fuel cell vehicles

Frequently asked questions

How is hydrogen generated?

What utilities are needed?

Also, instrumentation air may be required depending on the model.

What is the purity of the hydrogen produced?

Do we need to prepare pure water?

Since the HYSERVE can be equipped with a pure water system, tap water can be used.

What do we need in the event of periodic maintenance or an equipment failure?

What does the remote monitoring service include?

How long can the system operate continuously?

What do we need to do in the event of a machine malfunction?

Do we need to assign qualified personnel?