Utilizing the cryogenic temperature (-196°C) of liquefied nitrogen

Cryogenic and Freezer Grinding is applicable even to Food Materials with high moisture and oil content.

Pulverization of food materials while maintaining their unique taste, aroma and heat-sensitive components

FSSC 22000-certified factory

Cryogenic and freezer grinding is performed at the Cryogenic Grinding Center “Food Factory.”

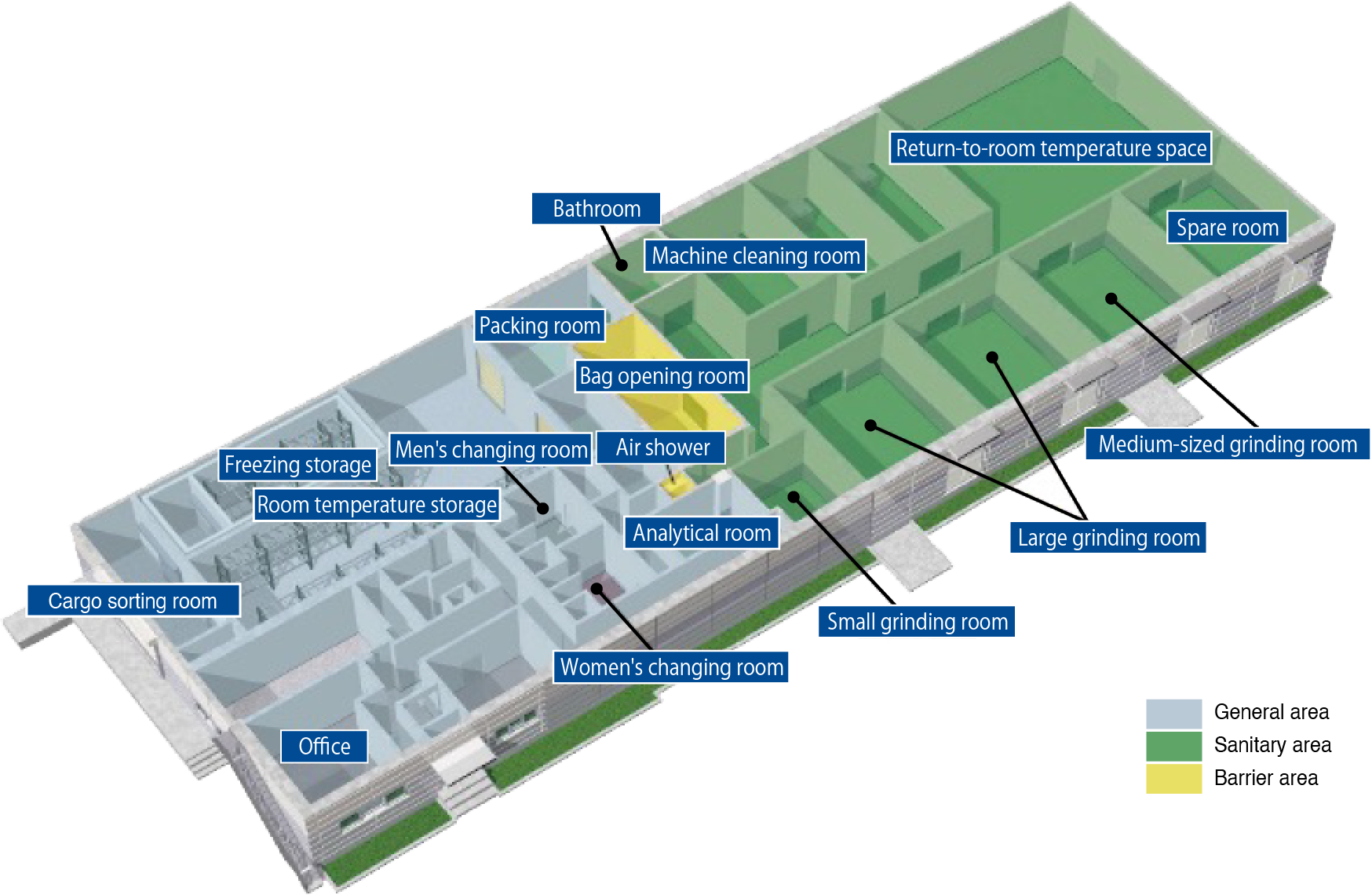

Secure, safe and highly efficient production system

Various measures are taken to prevent cross-contamination

(e.g., separating the general area from the sanitary area).

Furthermore, separate grinding rooms are used and individually air-conditioned

to prevent cross-contamination.

- Contract factory dedicated to food

- Grinding capacity from several kilograms to 3,000kg/time

Each machine is thoroughly disassembled and cleaned for each product.

- Grinding

- Disassembly of grinder

- Cleaning by hand

- ATP test

- Sprinkling of hypochlorite water

- Coliform group test

- Assembly

The Food Factory has been conducting quality control as an ISO 9001-certified factory along with the Resin Factory, and in February 2018, it obtained FSSC 22000* certification to achieve further food safety.

* FSSC 22000 is an international standard that encompasses the content of ISO 22000 and is strengthened by the addition of ISO/TS 22002-1 (or ISO/TS 22002-4) and additional requirements, and it has been approved by the Global Food Safety Initiative (GFSI).

Food Factory Food Safety Policy

We are sincerely committed to food security and food safety as a company involved in the food industry and contribute to society through our business activities.

・ We will comply with national and local laws, regulations and requirements related to food safety and keep our promises to our customers.

・ We will always strive for smooth communication with our customers, government agencies and employees and will appropriately communicate information on food safety to our customers and business partners.

April 1, 2021

Hiroaki Murase, Managing Director

History (Quality Chronology)

- 2004

- ・ Completed construction of the Cryogenic Grinding Center Food Factory

- 2005

- ・ Our ground fruits adopted for Suntory Spirits Ltd. canned cocktail

“-196˚C”

Canned cocktail

Photo provided by

Suntory Spirits Ltd.

- 2007

- ・ Obtained ISO9001 certification

- 2008

- ・ Introduced a metal detector

Metal detector

- 2013

- ・ Changed Production operations from subcontracting to in-house

- 2014

- ・ Introduced an additional metal detector

- 2018

-

・ Obtained FSSC 22000 certification to change the management system

・ Added a smaller grinder to meet the need for a wide variety of products in small quantities

・ Introduced an X-ray inspection machine

X-ray inspection machine

- 2020

-

・ Passed FSSC 22000 renewal audit

・ Established the Quality Committee, consisting of management members, to strengthen company-wide quality control

- 2021

-

・ Made quality control operation independent from the production division to establish the Powder Quality Control Division

・ Received commendation for "Excellent Food Hygiene-Related Facility" by Osaka Prefecture (Commendation from the Governor of Osaka Prefecture)

Letter of commendation for "Excellent Food Hygiene-Related Facility"

Canned cocktail

Photo provided by

Suntory Spirits Ltd.

Metal detector

X-ray inspection machine

Letter of commendation for "Excellent Food Hygiene-Related Facility"

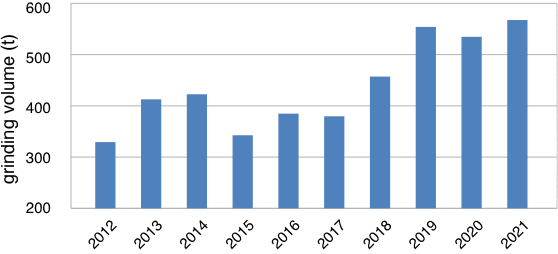

Changes in annual grinding volume

As the grinding volume increases, we are strengthening our commitment to quality

so that our customers can rely on us.