Processing technology for resins using the cryogenic energy of liquefied natural gas

Cryogenic and Freezer Grinding using liquefied nitrogen

Predrying using dry air with an ultralow dew point

Latest technology applications

Due to its dramatic technological improvement, Osaka Gas Liquid is pleased to introduce new solutions using cryogenic and freezer grinding.

As a leading company in cryogenic and freezer grinding, we will continue to propose solutions that meet the needs of the market.

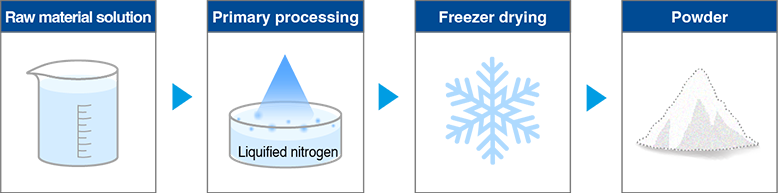

Liquid powdering technology

Drying frozen particles at low temperature makes it possible to turn raw materials into powder without heating.

Powdering flow

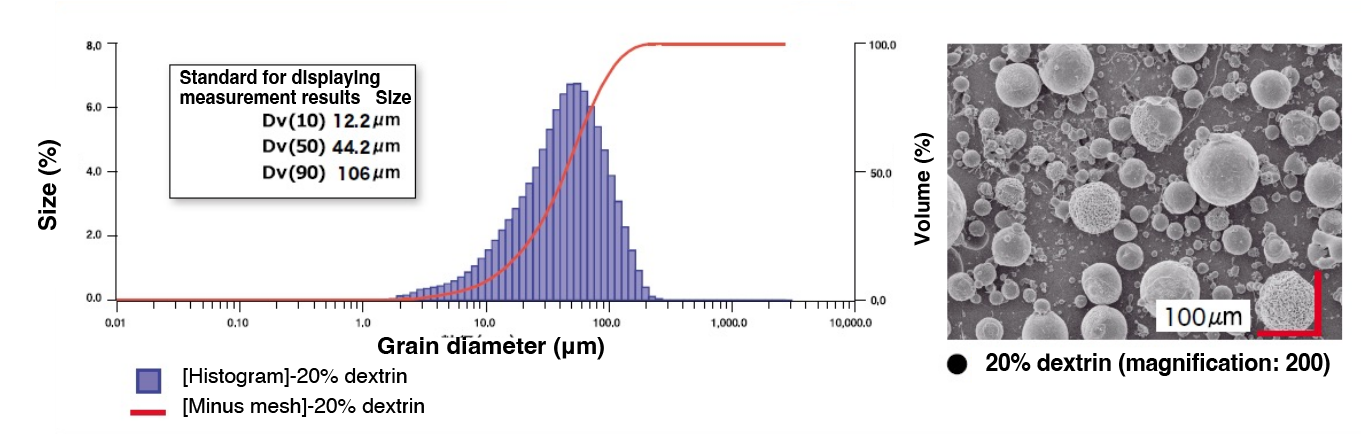

Measurement result of powdering

Advantage of the liquid powdering technology

- Unheated processing

- Compared to heated drying methods, degradation and alteration of active ingredients due to heat can be significantly reduced.

- Porous

- Since fine air gaps are created in the powder, solubility and dispersibility are expected to be improved.

- Uniform components

- No component separation or concentration gradient occurs during freeze-drying, reducing component ununiformity.

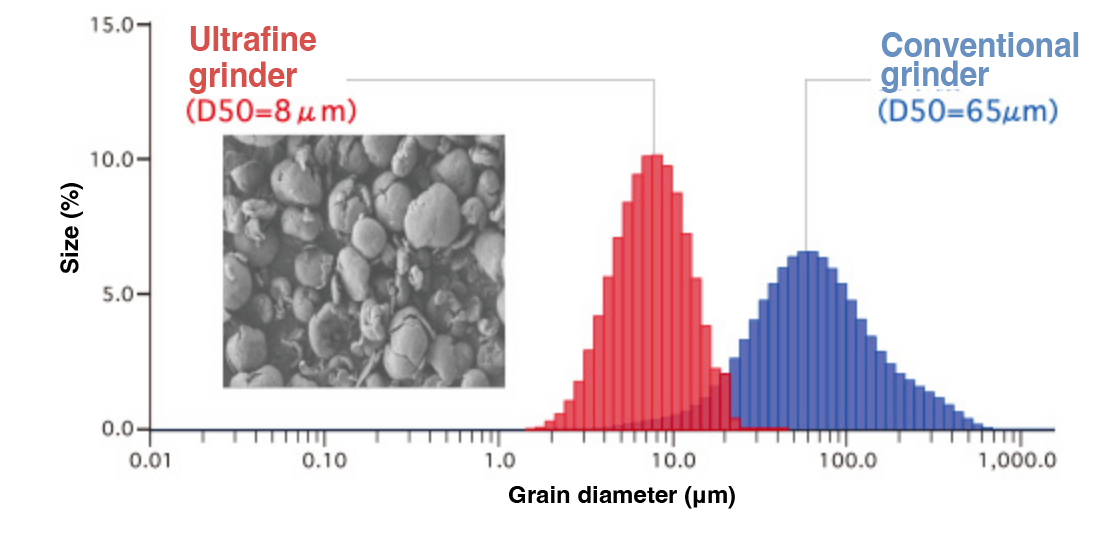

Ultrafine grinding of plastics

Further pulverization in the cryogenic and freezer grinding technique, namely ultrafine grinding

with an average particle size of 10 μm or less, is now possible.

Further improvement of various powder properties, including fluidity, impregnability and particle size distribution, is expected.

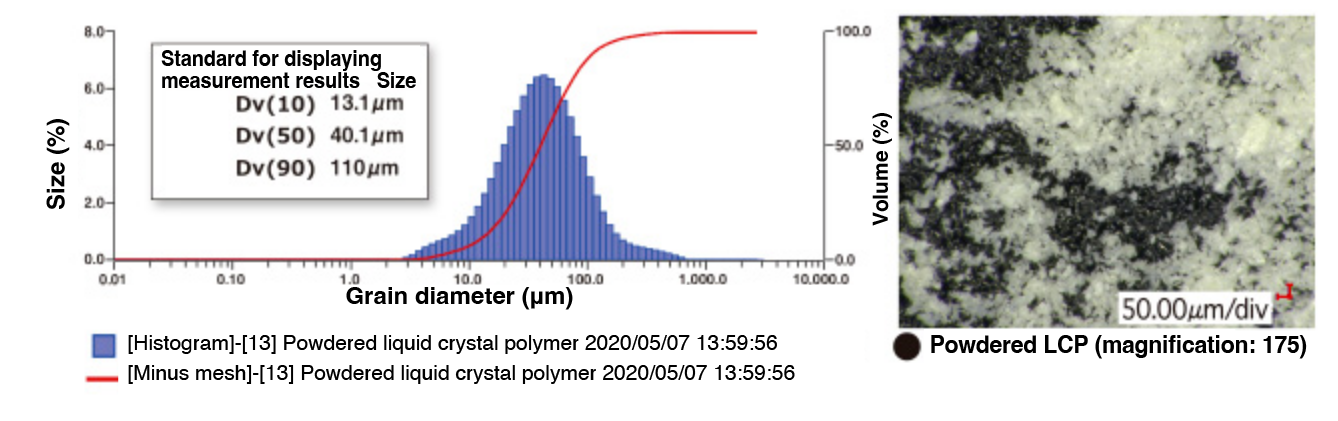

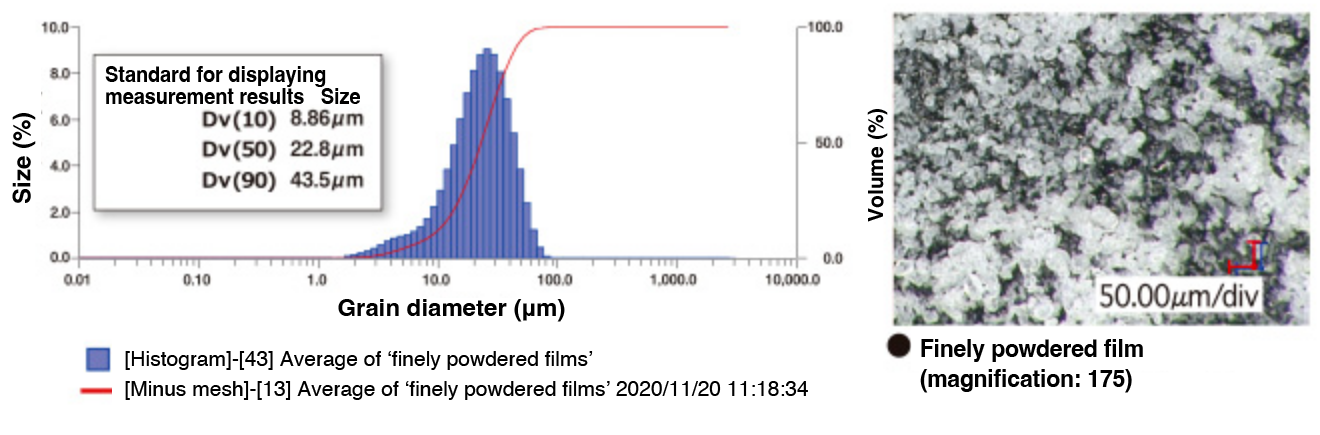

Measurement result of new ultrafine grinder performance

Grinding of liquid crystal polymer (LCP)

It had been difficult to grind LCP because its molecular chains are oriented in one direction,

and when it is ground, it becomes fibrillated.

As a result of searching for a new grinder and technological development, we have succeeded in powdering LCP.

Grinding of various types of films

With the conventional method, films could not be ground because they stagnated inside the grinder,

which eventually caused an internal blockage.

However, we have made fine grinding possible through man-hour improvements and original ideas.

Expansion of accepted materials

- Water soluble materials

(PVOH, etc.) - Colored materials

(Black, gray, etc.)

Please contact us about the projects that you have abandoned for grinding!

Track record in grinding

Here are some of the materials that we have ground.

All are ground under the same conditions (machine conditions for finest quality);

however, the particle size varies depending on the material.

Click on the material name below to view details.